Fortgeschrittenes segmentiertes Design der medizinischen Präzisionskatheterscheide: Erforschen der perfekten Balance zwischen Stabilität und Flexibilität

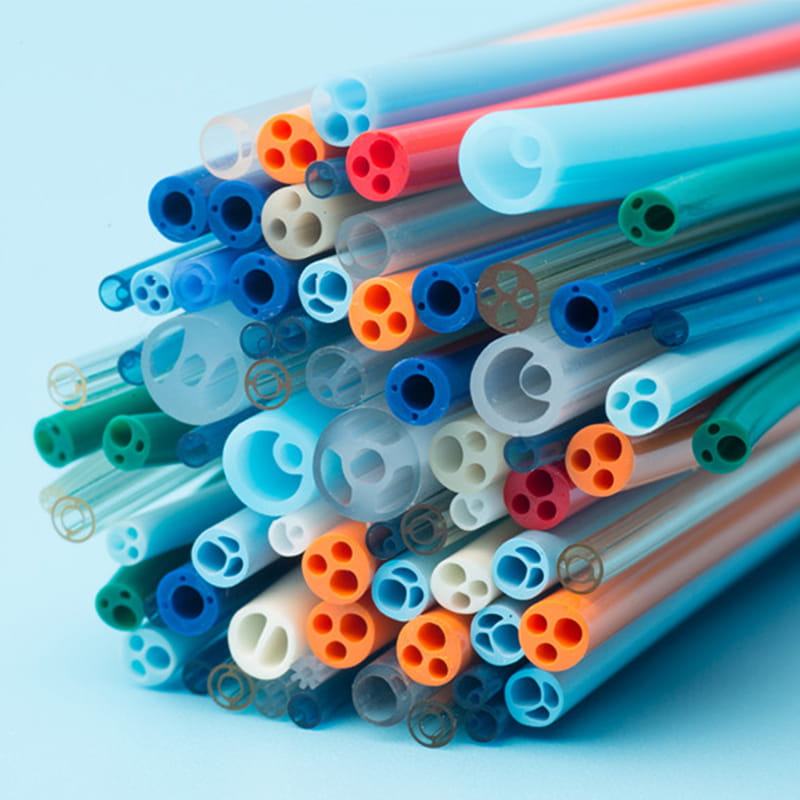

1. Außenschicht Design: Intelligente Auswahl der Polymermaterialien

Die äußere Schicht von medizinische Präzisionskatheterscheide wird normalerweise aus fortgeschrittenen Polymermaterialien hergestellt. These materials not only have excellent biocompatibility to ensure the safety of patients during use, but also optimize the mechanical properties through fine formula adjustment. The selection of polymer materials, such as polyurethane, polytetrafluoroethylene (PTFE) and its modified materials, gives the outer layer of the catheter sheath a stable support force, enabling it to maintain a stable shape in the blood vessel and not easy to collapse or twist. At the same time, these materials also show good flexibility and elasticity, allowing the catheter sheath to flexibly conform to the bends and bifurcations of the blood vessels, reduce damage to the patient's vascular wall, and improve the comfort and accuracy of the surgical operation.

Darüber hinaus ist die Oberflächenbehandlungstechnologie des Außenschichtmaterials ebenso wichtig. For example, the application of coating technology can increase the lubricity of the catheter sheath surface, reduce friction, further promote its smooth movement in the blood vessel, and reduce the risk of thrombosis, providing a strong guarantee for the successful implementation of the operation.

2. Struktur der Zwischenschicht: Innovative Verschmelzung von Doppel -Edelstahl -Stahl "Federwicklung Flechten"

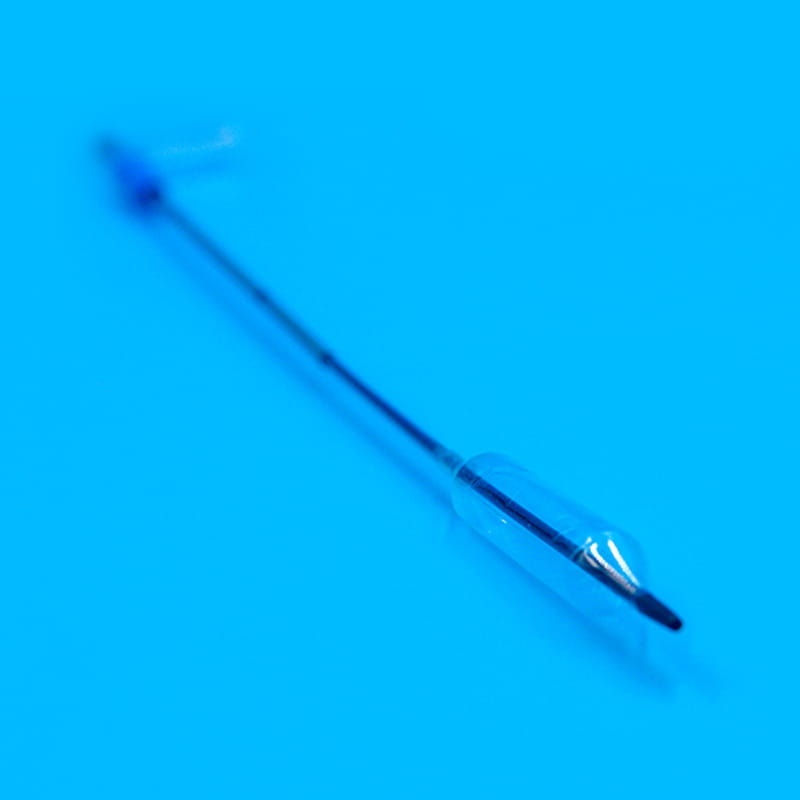

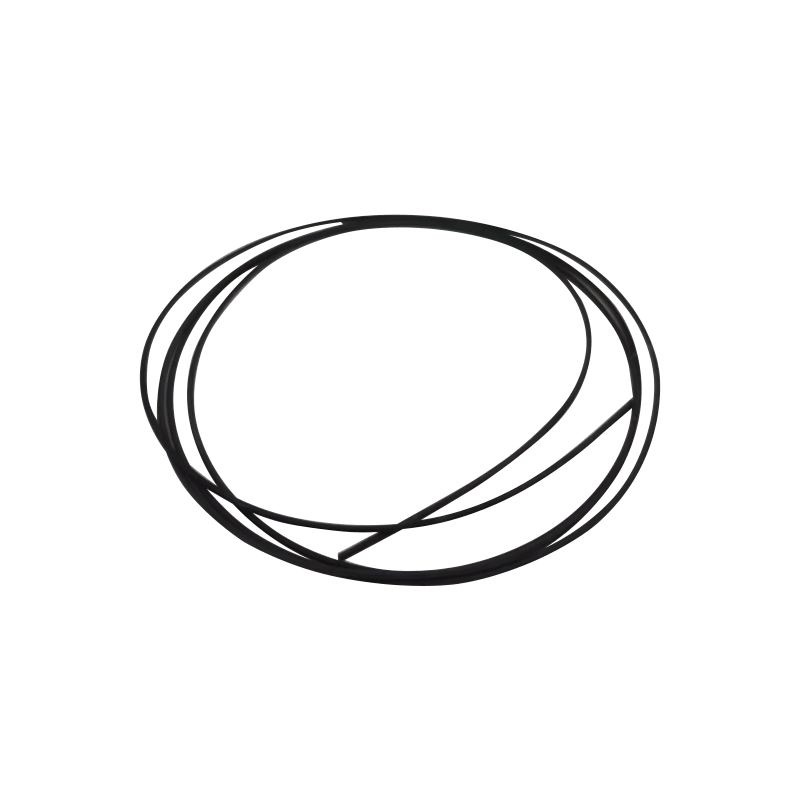

If the choice of outer layer material lays the foundation for the basic performance of the catheter sheath, then the structural design of the intermediate layer is the key to its performance improvement. In medizinischen Präzisionskathetermännern verwendet die Zwischenschicht häufig eine doppelte Edelstahl -Stahlstruktur "Federwicklung". This design cleverly combines two different forms of metal reinforcement methods, greatly enhancing the stability and durability of the catheter sheath.

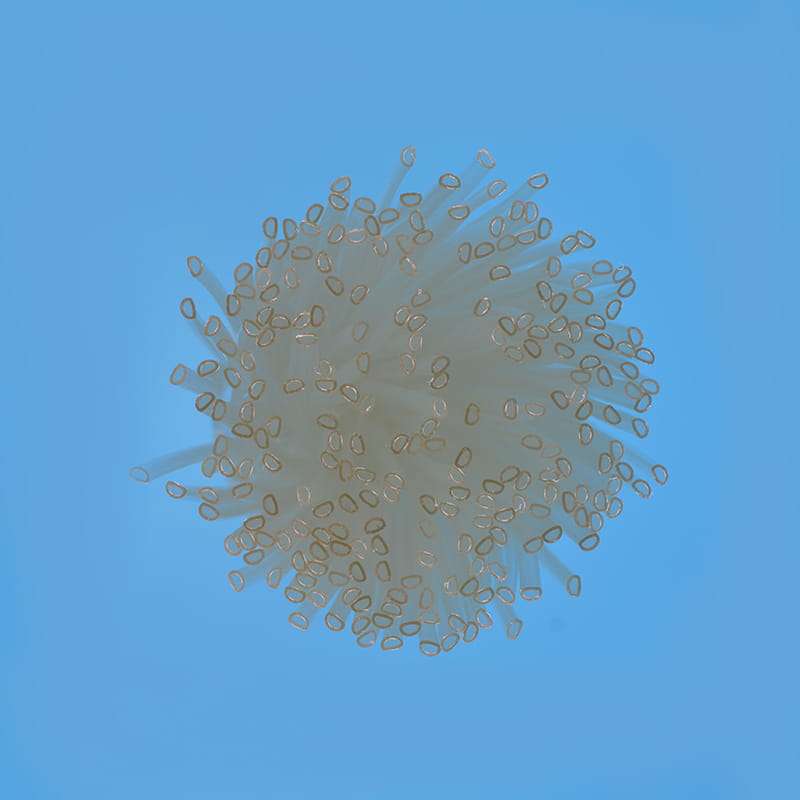

The spring winding structure, that is, winding the stainless steel wire into a spiral shape, as the intermediate support layer of the catheter sheath, can effectively resist the lateral pressure of the vascular wall on the catheter sheath, prevent its deformation during operation, and maintain the accuracy of the path. The braided structure, on the other hand, forms a mesh structure by cross-braiding stainless steel wires, which further improves the torsional stiffness and torsion resistance of the catheter sheath, allowing doctors to more accurately control the rotation and direction of the catheter sheath during operation, and achieve precise navigation even in extremely complex vascular environments.

This combination of double structures not only strengthens the mechanical properties of the catheter sheath, but also achieves good blood fluidity and biocompatibility through the tiny gaps between the metal wires, reducing the risk of postoperative complications. At the same time, the design also gives the catheter sheath a certain radial expansion ability, so that it can adapt to blood vessels of different diameters, improving the adaptability and success rate of the operation.

3.. Umfassende Vorteile des segmentierten Designs

The segmented design of the medical precision catheter sheath achieves a perfect combination of stable support and soft adaptation through the careful matching of the outer layer polymer material and the middle layer double stainless steel structure. This design not only improves the operating performance of the catheter sheath, but also reduces the difficulty of surgery, shortens the operation time, and brings patients a safer and more effective treatment plan.

Für weitere Informationen rufen Sie uns bitte unter +86-18913710126 an oder senden Sie eine E-Mail an [email protected].

A medizinischer Ballonkatheter ist ein hochentwickeltes medizinisches Gerät, das zu...

Einführung Die TPU-Reduzierrohr (Thermoplastisches Polyurethan-Reduz...

In der modernen Medizin sind medizinische Katheter unverzichtbare Hilfsmittel für eine Vielzahl v...

In der Gesundheitsbranche kann die Bedeutung der Auswahl der richtigen Materialien für medizinisc...

Im Zeitalter der Präzisionsmedizin trägt ein kleines Röhrchen oft die Last lebensrettender Aufgab...

Im modernen Gesundheitswesen ist ein präzises Flüssigkeitsmanagement von entscheidender Bedeutung...